Manufactured in the UK

Our Mini greenhouses and Cold Frames are manufactured in Northamptonshire in the UK. We are proud to still make our products in Britain and are members of the Made in Britain association.

The original Cold Frames were designed for growing early Strawberries and we are still located on the original nursery site in the village of Crick.

Made in Britain Membership

We have been manufacturing cold frames and Mini greenhouses on our site in Crick since the late 1950’s.

As part of our commitment to UK manufacturing, we are members of the Made in Britain organisation, which was founded to promote UK manufacturing around the world.

Our membership allows is to display the converted Made in Britain logo on our products and promotional material.

Our Factory

Inside our factory we turn aluminium extrusions, glass sheets and multiple components into finished greenhouses ready to be shipped around the UK and the world. Our dedicated team members cut, punch, powder coat and pack the aluminium parts. Fixings and smaller components are added to the framework packs before being despatched with the toughened safety glass for glazing. Products are then shipped via UK carrier or on a pallet to overseas destinations.

Sawing the aluminium

The aluminium is extruded to our own profile designs and shipped from the mill in long lengths.

These long lengths are then sawn down into smaller parts for the greenhouse using a hydraulically operated saw. Some items are mitred for easier and neater assembly.

Smaller components and sheet aluminium items are supplied to us laser cut, ensuring accuracy and consistency.

Punching

Thicker profile aluminium extrusions used for the main greenhouse structure have their fixing holes punched using bespoke hydraulic piercing units. Heavy duty frames hold the piercing units, producing a clean and quick holes into the sections.

Picking and Packing

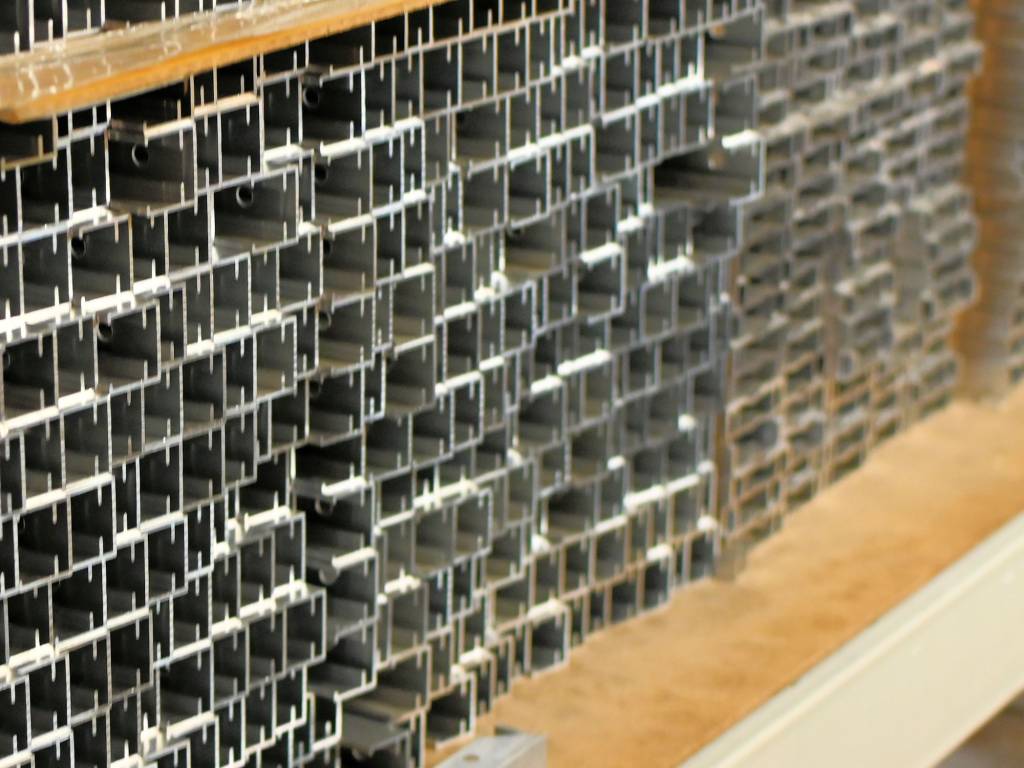

Once the main components are made these are stored on racks for later packing of the greenhouse.

All of the parts components need to be picked into sub packs, each greenhouse will be made up of hundreds of small components such as nuts, bolts, spacers and watering fittings.

Once the greenhouse is ready to be packed, all of the large and small parts are packed together in boxes, ready for shipping. Some of the smaller greenhouses all fit into a single box, but larger greenhouses have a number of packs.

Powder Coating

Our aluminium framework is guaranteed for 25 years, but our greenhouses can be powder coated to blend in – or stand out! – in the garden.

We use a high quality polyester powder powder coat which is backed on to the aluminium components.

There is plenty of preparation required for the surface before the powder can be applied. After degreasing the components, the parts are hung on jigs to allow an acid etch to be sprayed onto the parts. This provides a ‘key’ for the powder to adhere to.

Once the etch has cured, the aluminium is coated with the polyester colour coating using a specialist powder coating gun that electrically charges the powder particles.

Once all of the parts are fully coated, the racks of components are loaded into the oven and baked for 20 minutes. The items are allowed to cool before they are unloaded.

Glass Packing

To ensure the greenhouse glass arrives safely the glass has to be packed into smaller packages. Specialist padding around the glass protects the edges of the glass, which are the most vulnerable parts of a toughened glass sheet.

Greenhouse Despatching

Once the greenhouse is ready for despatch, the frame packs and the glass pack are picked and the consignment is despatched via carrier. We use several UK carriers plus the pallet delivery network for larger orders.

Once the order had been entered into the carrier system, our office keep an eye on the tracking to ensure safe delivery, and to sort out any issues. We provide a safe delivery guarantee to ensure you will always get all of your parcels.

For peace of mind, we also offer an after sales service that is able to provide accessories and spares for the greenhouse, even for models that are 20 or 30 years old.